Product Description

Course Duration: 6 Month

Time: 4 Hrs.

Diploma in DIGITAL DESIGN / PRODUCTION Technology :

Introduction of Basic Engineering Drawing

- Drawing Instrument / Sheet Layout / Geometrical Construction

- Orthographic Projection / Projection of Planes / Solid s / Surface.

- Engineering Drawing Reading and Practice

Introduction to Engineering Draining

An engineering drawing, a type of technical drawing, is used to fully and clearly define requirements for engineered items.

Engineering drawing (the activity) produces engineering drawings (the documents). More than merely the drawing of pictures, it is also a language—a graphical language that communicates ideas and information from one mind to another. Most especially, it communicates all needed information from the engineer whodesigned a part to the workers who will make it.

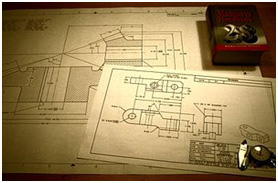

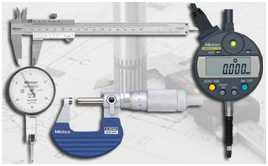

Live Measurement with variant instrument and Drafting GD & T.

- Different type of measurement technology and Instrument like Veriner/ Micro meter / Radius Gauge / Thread Gauge etc.

- Practical usage with variant components.

- Introduction for GD & T …

Different type of measurement technology and Instrument like Vernier / Micro meter / Radius Gauge / Thread Gauge etc.

Practical usage with variant components.

Measurement begins with the definition of the measured, the quantity intended to be measured. The specification of a measured requires knowledge of the kind of quantity and a description of the object carrying the quantity. When the measured is defined, it must be related to a measurement standard, the realization of the definition of the quantity to be measured. The measurement procedure is a detailed description of a measurement according to a measurement principle and to a given measurement method.

Limit / Fit / Tolerance.

Two extreme permissible sizes of a part between which the actual size is contained are called limits.

The relationship existing between two parts which are to be assembled with respect to the difference on their sizes before assembly is called a fit.

Tolerance is defined as the total permissible variation of a size. It is the difference between maximum limit and minimum limit of size

Starting with AUTO CAD and Detail Drafting.

At SUNCAD, we help you ace the accompanying features of AutoCAD 2D:

- Creation of 2D drawings

- Adjustments utilizing altering instruments

- Layer administration

- Dimensioning

- Hatching

- Using parametric limitations

- Create and oversee sections

- Administer Extrinsic references

- Plotting

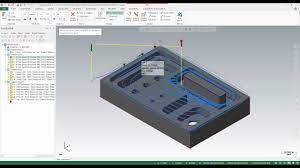

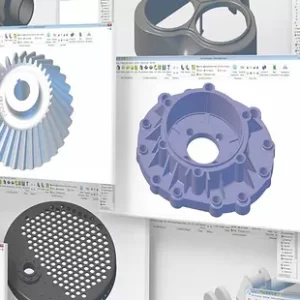

Detail Training on SOLID WORKS.

At SUNCAD, we help you master the following compatibilities of SolidWorks:

- CAD Animation:How to create a 3D, animated movie of your product design

- Product Data Management:How to keep, reuse, repurpose all design data in a secure way

- Revision Control:How to keep track of the changes you make to your evolving product design, and also monitor changes each revisions bring to your overall design and manufacturing cost

- Costing:How to check your design against manufacturing cost, and how to automatically generate manufacturing cost, as you design

- Part and Assembly:How to design parts and assemblies of parts

- Tolerance Analysis:How to analyze the tolerance levels of each individual part separately, as well as all that of parts when functioning collectively.

- CAD Library:How to increase productivity by making use of CAD library

- Interference Check:How to check the way all parts fit among themselves, and operate as intended

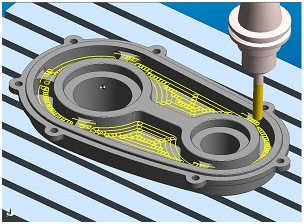

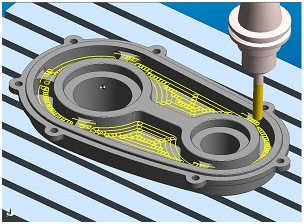

Detail Training on CAM of MASTER CAM.

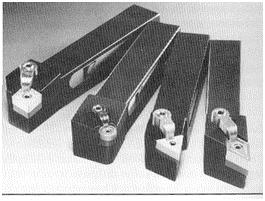

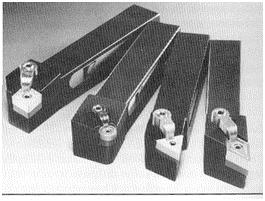

Cutting Tool Technology

What is a Cutting Tool?

- A cutting tool is any tool that is used to remove metal from the work piece by means of shear deformation.

- It is one of most important components in machining process

- It must be made of a material harder than the material which is to be cut, and the tool must be able to withstand the heat generated in the metal cutting process.

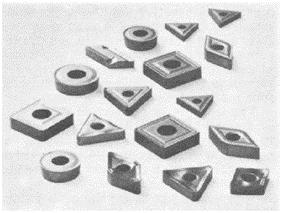

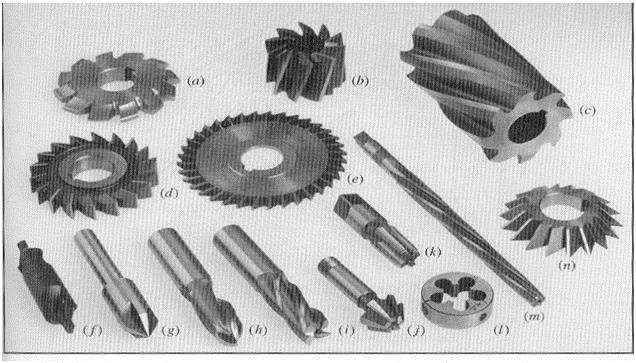

Two basic types:-

- Single point

- Multiple point

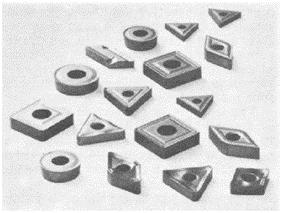

Single Point Cutting Tool:

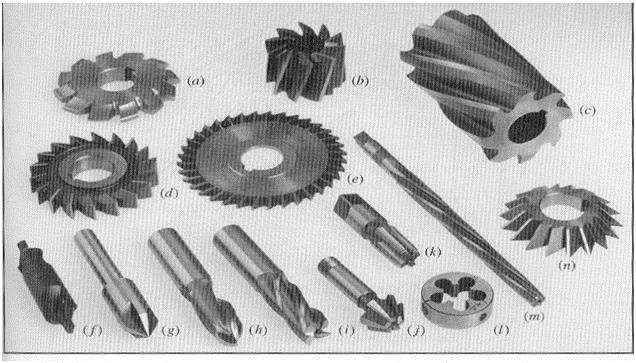

Multi Point Cutting Tool:

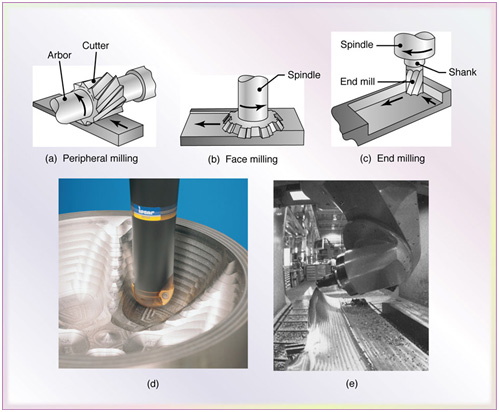

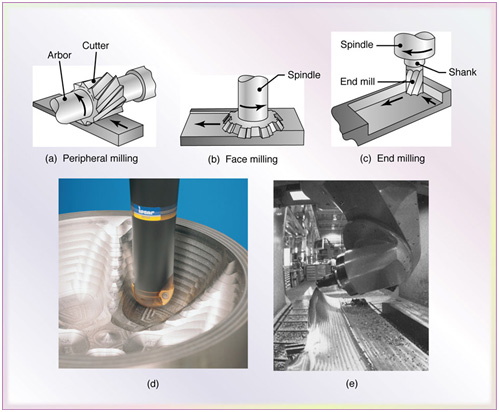

Manual CNC Milling Programming :

- Milling: a process in which a rotating multi-tooth cutter removes material while traveling along various axes with respect to the work piece.

- In peripheral milling (also called plain milling), the axis of cutter rotation is parallel to the work piece surface. When the cutter s longer than the width of the cut, the process is called slab milling.

Master CAM machining / Live CNC Machining with CAM software.

Manual Machine operating and Live JOB preparation.

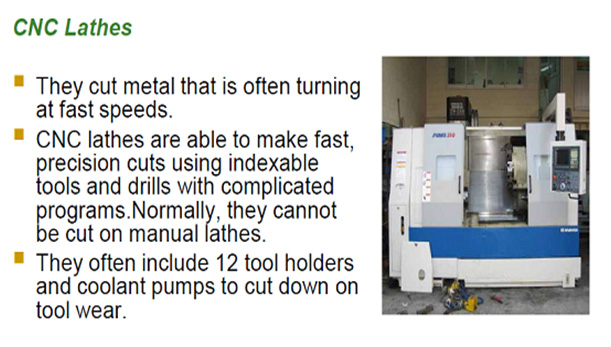

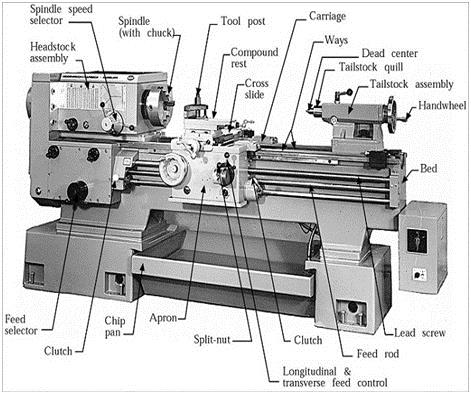

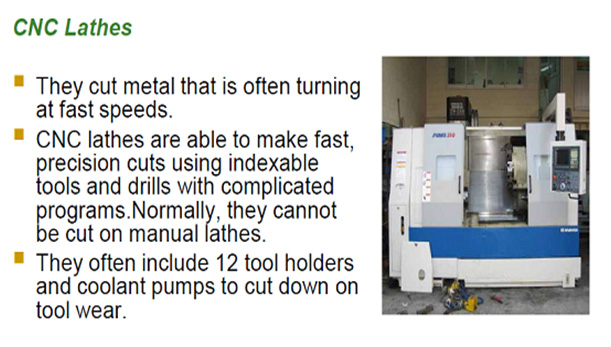

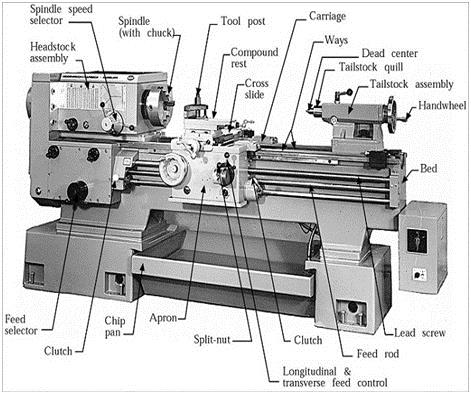

Manual CNC Programming for CNC Lathe.

Lathe is considered as one of the oldest machine tools and is widely used in industries.

It is called as mother of machine tools. It is said that the first screw cutting lathe was developed by an Englishman named Henry Maud slay in the year 1797.

The primary task of a lathe is to generate cylindrical work pieces. The process of machining a work piece to the required shape and size by moving the cutting tool either parallel or perpendicular to the axis of rotation of the work piece is known as turning. In this process, excess unwanted metal is removed. The machine tool useful in performing plain turning, taper turning, thread cutting, chamfering and knurling by adopting the above method is known as lathe.

Introduction on 3D Scanning

We Offers high quality 3D scanning services for a wide variety of applications and needs.

The results of scanning can be offered as copious point cloud data or orderly sections along principal planes or parallel to any user defined plane. Point cloud can also be given as tessellated STL file. The point cloud data generated can be reliably read into all industry standard CAD packages for further processing.

- Reverse engineering services

- Quality control & 3D inspection services

- Surfacing modelling & solid modelling

- Class A surfacing

- Rapid Prototyping services

- Product design services

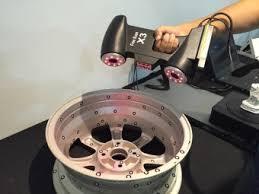

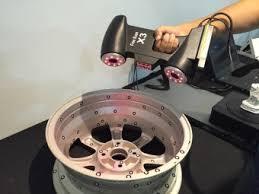

Live trial on 3D Scanning with 3D Reverse Engineering

3D Scanning (Laser and White Light / Blue Light Scanning)

We have a complete toolset for turning raw 3D scan data into high quality, watertight polygon mesh models for use in downstream applications, including Scanning / Inspection software.

live Scan technology for real-time data capture with several popular 3D scanners

- Comprehensive point cloud clean up tools

- Triangulation technology to convert point clouds into polygon mesh models

- Multi-scan registration to align all scan shots together

- Advanced multi-scan merging to create complete, non-overlapping polygon mesh models

- Intelligent hole-filling, including curvature based filling

Polygon mesh healing wizard

- Decimation technology to intelligently reduce data sizes

Massive data handling capabilities (>30M polygons) and fast processing times with dual CPU support

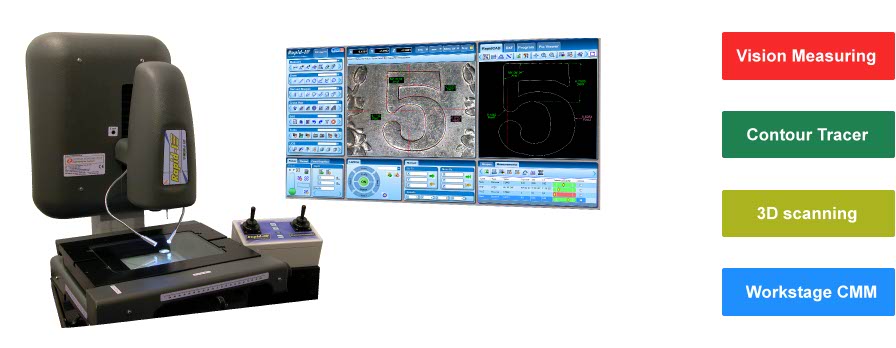

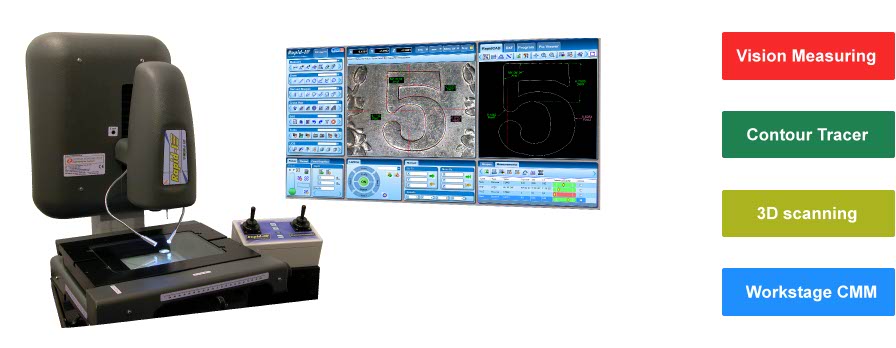

Introduction on 3D Inspection

Live Inspect technology for real-time inspection results from handheld 3D scanners.

- On-the-fly deviation colour mapping while scanning

- Automatic feature detection and GD&T

- smart Guide on screen prompts for guided 3D scanning

Automatic scan data alignment

- Datum-based, 3-2-1, RPS or best fit method

3D & 2D deviation analysis

- Color map and deviation vector display

- Multiple tolerance levels and interactive colour coding

- Supports ANSI Y14.5B 1994 standards

3D & 2D GD&T

- Drag and drop report generation, with export to PowerPoint, Excel and PDF

- 3D HTML reports for sharing inspection results via a web browser with embedded 3D models

- One step repeat of entire inspection process

Live bench mark on Portable CMM.

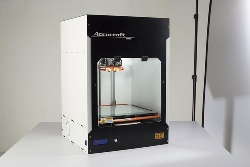

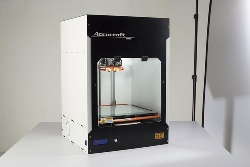

live 3D Printing

A GUARANTEED OUTCOME

From full colour concept models to functional prototypes and complex 3D printed end use parts for manufacturing applications. Our 3D solutions including printers, software’s and services to help streamline the design process and deliver products to market with speed and precision.

END-USE PARTS

Innovative companies across a wide range of industries are using production 3D printing to deliver end use parts and custom products today. For high value, low volume rapid manufacturing or mass customization – it’s available…

PROTOTYPING

3D Systems options for prototyping verify designs for form, fit and function prior to full-scale production; plus reduce costly modifications to production tooling. No matter how challenging your project – we have a solution for you.

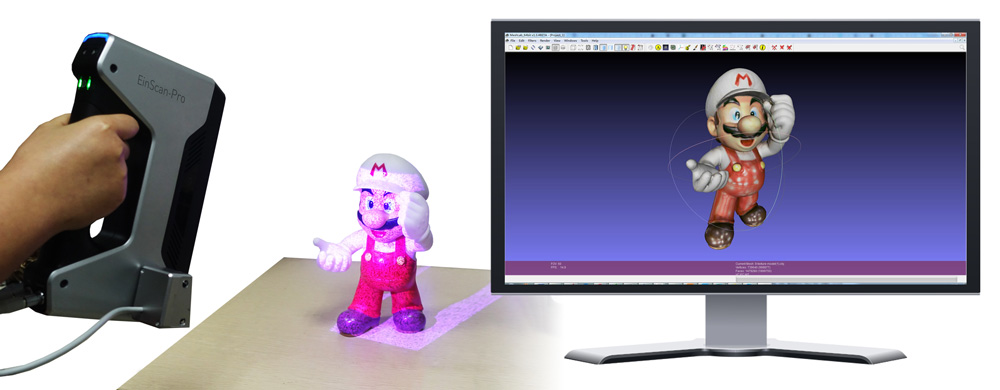

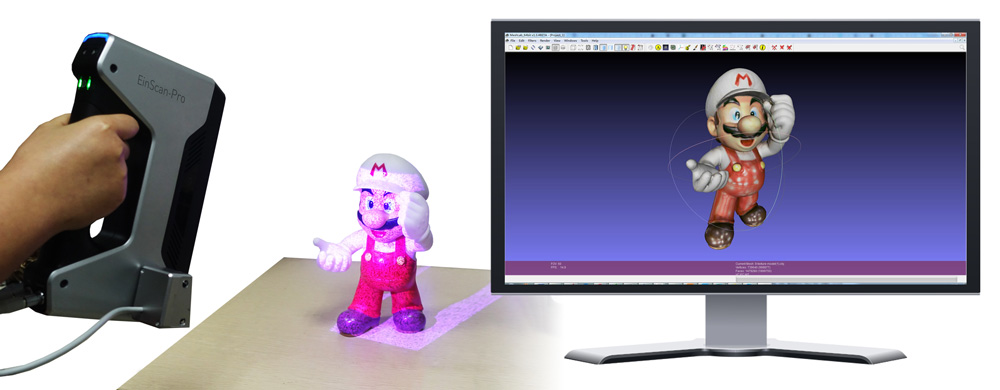

EinScan-Pro Multi-Functional Handheld 3D Scanner

The EinScan-Pro is your best choice for capturing real world data to convert into a digital 3D model. It can be used for consumer and commercial applications in manufacturing, engineering, design, development, testing, artwork archival, animation and even human form acquisition. The EinScan-Pro 3D scanner allows you to use physical objects to better conceptualize an idea or create a starting point for modeling in CAD (Computer Aided Design).

Leica absolute tracker AT 402

The Leica Absolute Tracker AT 402 is a portable coordinate measuring machine that allows extreme precision, over ultra large distances. It is able to be powered by its own internal battery and is able to work in the most demanding environment, yet maintains the highest level of precision and the largest ever work envelope. The Leica Absolute Tracker AT 402 has a unique “All in One” system design that incorporates such needed accessories as built in live video, level to gravity, environmental monitoring and even an integrated IR remote control. By utilizing the integrated Wireless LAN communication the sensor can be used completely wirelessly making this the most portable.