Automation Design

Our products enable a wholistic engineering of production systems from mechanical concept through to complete PLC code. Discover a whole new level of collaboration with a toolset that enables a complete machine and plant design workflow, providing the highest level of design quality in the shortest time possible. Automation Designer offers a one-of-a-kind engineering toolset, designed from the ground up to enable controls engineers to complete their work with the highest efficiency, quality and speed possible.

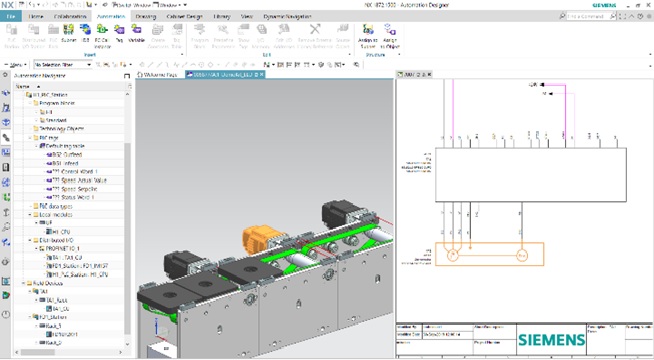

Electrical and automation engineers work on the same backbone, with an integrated data model, saving time and eliminating errors. Directly integrate mechanical engineering data and receive updates, improving collaboration across your organization. Our integrated system also improves the quality of engineering results, while increasing efficiency by combining mechatronic models of existing designs and rule-based engineering to eliminate non-value added work. This, combined with our NX virtual commissioning capabilities, makes the complete process from concept to reality faster than ever before.

Our integrated system improves the quality of engineering results. See the capabilities below.

Automation Design

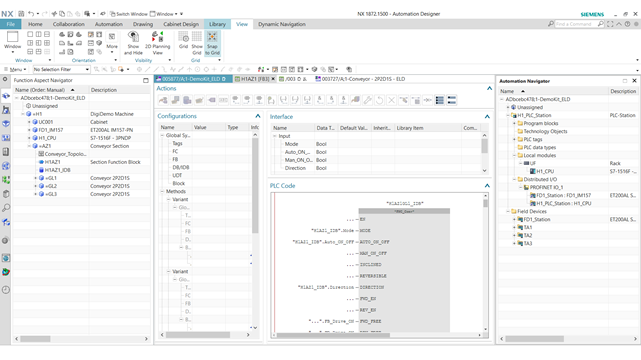

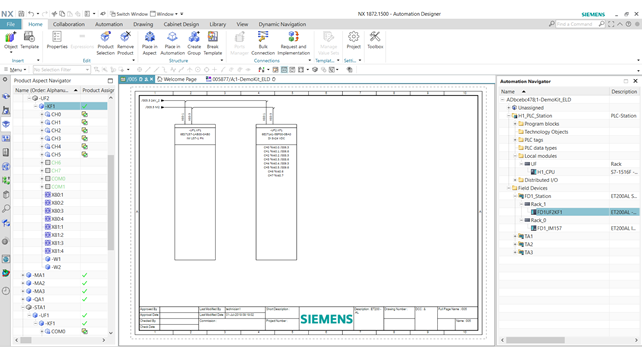

Automation Designer allows for the direct integration of existing Siemens TIA Portal libraries and data. This allows for accelerated automation design.

- Manage TIA Portal data directly

- Integrate and reuse TIA Portal global libraries

- Export HW to TIA Portal directly from the electrical design

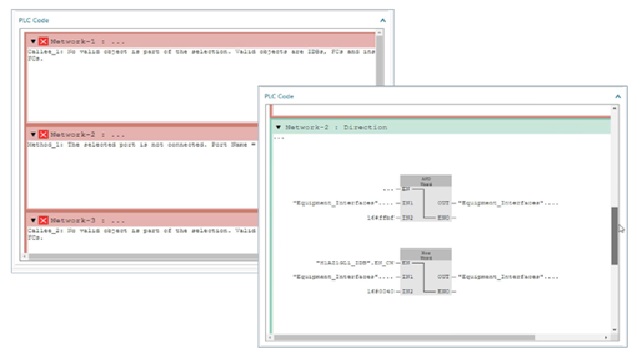

- Powerful rules-based PLC code creation and dynamization

- Code-less import/export of software and hardware to TIA Portal

Users of non-Siemens PLCs benefit from the export of signal and hardware information from the completed electrical design.

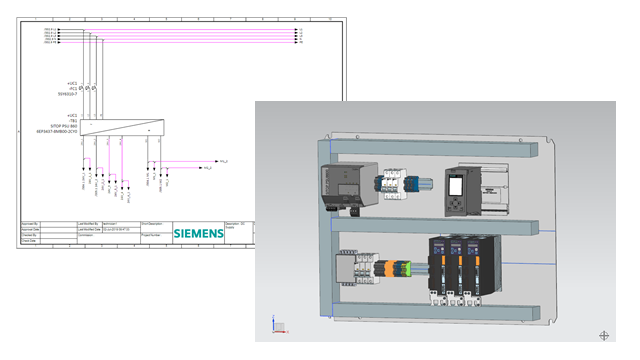

Electrical Design

The central task of an electrical engineer is the design of electrical systems to bring the machine or line to life. With Automation Designer and it’s integration to EPLAN or through the NX Electrical Design Add-on, the electrical engineer can complete the design of the electrical system, while simultaneously completing the automation design.

- Define electrical infrastructure and catalog parts

- Define PLC Configuration

- Create electrical schematics

- Create 3D cabinet designs

- Create manufacturing documents

Functional Engineering

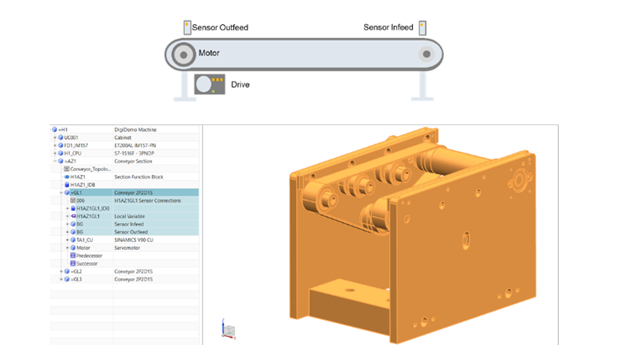

Functional, mechatronic design has a new meaning in Automation Designer, with model-based definition of functions.

- Define function, location and product structures

- Create relationships between objects

- Reuse and combine data between objects to automate design processes

Integrated Data Model

Manual data transfer and double-work cause bottlenecks, slowdowns and unproductive time in a project. With a fully integrated electrical and automation data model, Automation Designer enables single engineering workflows that complete the work of multiple disciplines simultaneously. This increases efficiency and eliminates non-value added double work.

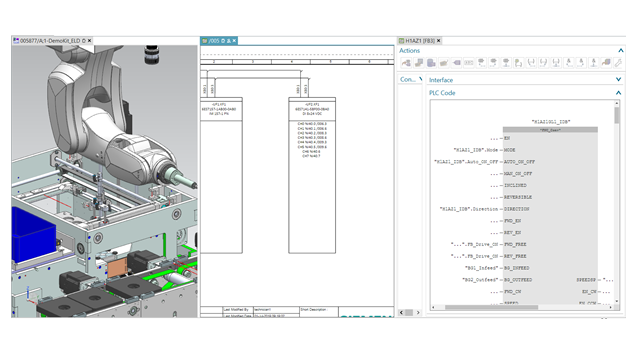

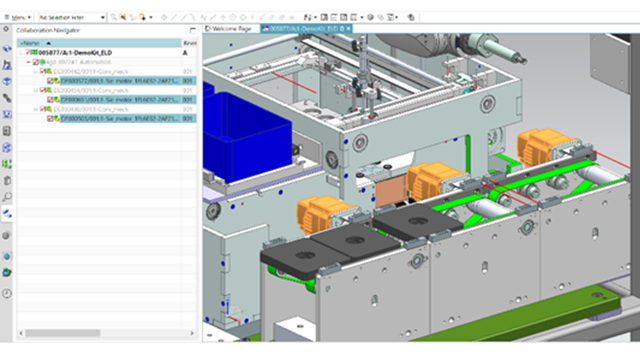

Mechanical Design Integration

Integrate mechanical designs directly into your work through a common data backbone.

- Quickly identify electrical/automation relevant components

- 2-click addition of electrical and automation data

- Perform effective change management with simple, integrated workflows

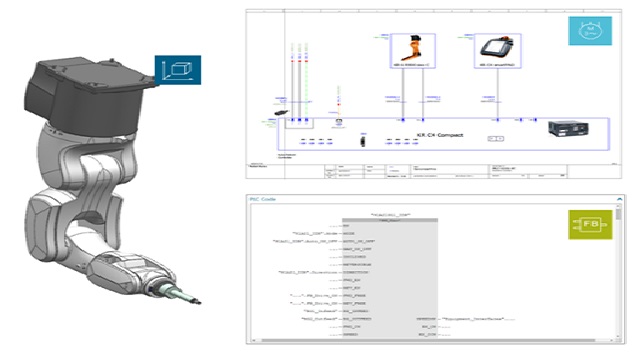

Mechatronic Templates

Standardization of engineering designs within single disciplines has brought improvements in the speed which new designs are created but is limited to incremental improvements of single disciplines. The ability to create mechatronic templates enables a new level of standardization, which significantly reduces engineering efforts and maintains unparalleled consistency of the entire design. It enables library objects that span design data from multiple disciplines.

Multidisciplinary Collaboration

Collaboration between disciplines is one of the most difficult and costly issues faced by machine and line builders today. Automation Designer addresses this issue by enabling mechanical, electrical and automation designers to simultaneously review, discuss and collaborate on their design. This breaks down barriers in the design process and helps teams collaborate more effectively and execute projects more efficiently.

Rule-based Engineering

The quality of engineering designs often suffers from errors caused in non-value added, repetitive activities. These actions, such as the definition of reference designations and symbolic names or even the creation of software or schematics can be automated through your design rules. This allows engineers to reduce errors and gives them more time to focus on creating value and driving innovation.

NX for Design

The most powerful, flexible, and innovative product development solution in the industry, NX for Design has the features, performance, and capabilities to help you get product to market faster than ever before.</div>